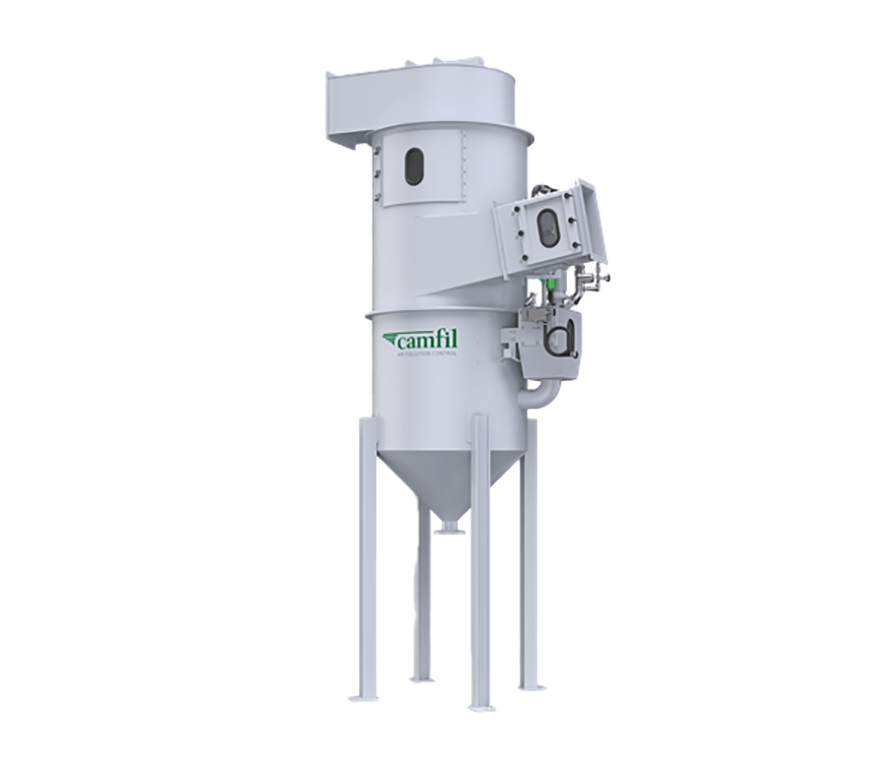

Camfil Handte Venturi Wet Scrubbers

Overview

The Handte Venturi wet scrubber is designed for high dust loads and functions according to the Venturi principle. In the upstream Venturi zone, the scrubbing water is injected into the exhaust airflow, disrupted by the increase in velocity of the air, and disintegrated into water droplets. The high velocity between the polluted exhaust air and the water droplets in the Venturi throat causes the pollutants to bind with the water droplets.

The polluted exhaust air is introduced tangentially with the polluted scrubbing water to the downstream demister unit and separated by the active centrifugal forces. The purified exhaust air is moved and discharged by the downstream ventilator positioned on the clean gas side. The separated pollutants are fully or partially isolated in the collecting area of the scrubbing water through sedimentation processes. They can be disposed of using various discharge systems.

Benefits

- For medium to ultrafine particle dimensions

- Separation of up to 0.5 µm

- Optimum separation due to water injection in the Venturi zone

- No reduction in performance. The ventilator ensures efficiency.

- Resistant to contamination due to the demister unit in the water cyclone at vertical surfaces

- Unique ventilator design suitable for swirl flow

- Excellent accessibility facilitates easy maintenance

Applications

- Flammable and explosive dusts

- Steel dusts

- Aluminum

- Sticky powders

- Greasy vapors

- Magnesium and titanium dusts