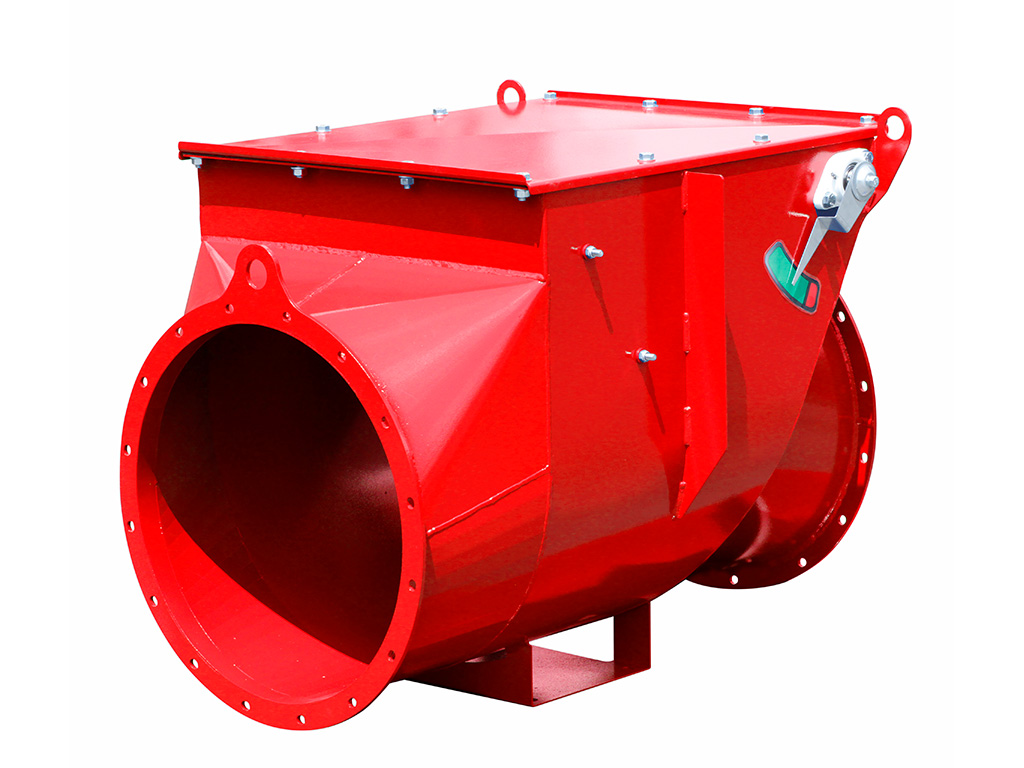

Vigiflap Explosion Isolation Valves

Overview

The Vigiflap is an explosion isolation valve designed to prevent propagation of overpressure or flame front caused by an explosion downstream in vessels such as dust collectors, cyclones, and filters.

The valve is held open either by air flow or proprietary locking mechanism. As a result, the Vigiflap valve can be used as an explosion isolation device for both the inlet and oulet of a vessel.

The Vigiflap Explosion Isolation Valve complies with NFPA guidelines and is an ATEX Certified device for the containment of explosion.

Features

- Body: Painted steel

- Diameters: ø6” to ø54” / ø160 mm to ø1350 mm

- Gasket: EPDM (Silicone FDA 356°F/180°C option)

- Pressure drop: Lower pressure drop with round domed flap

Optional Features

The Vigiflap is 100% NFPA 69 compliant with the following optional features:

- Body: Galvanized or Stainless steel

- Frame silicone FDA: 356ºF/180 ºC

- Dust level sensor to prevent dust accumulation

- Connection box installed on the body, according to the ATEX zone (opposite side of the locking mechanism)