Control Combustible Dust with Filtration Systems

Combustible dust can be comprised of many types of fine material that can ignite and explode when mixed with air. Explosive particles can come from:

- Many metals, such as aluminum, zinc, magnesium, and bronze

- Many organic materials, such as wood, grain, flour, and sugar

- Some non-metallic, inorganic materials, such as silicon, cobalt, and bismuth

Although some of these materials are not typically combustible, they can explode if their particles are the right size and in the right concentration. For this reason, if your company is using processes that create dust, you need to be aware of any risks that it may explode. When making your assessment, bear in mind that dust can collect on surfaces, such as:

- Suspended ceilings

- Roof interiors

- Beams and rafters

- Ducts

- Dust collection units

- Other equipment

If dust is allowed to collect, even in a small amount, when it’s disturbed there is a potential for a serious explosion that can injure your employees.

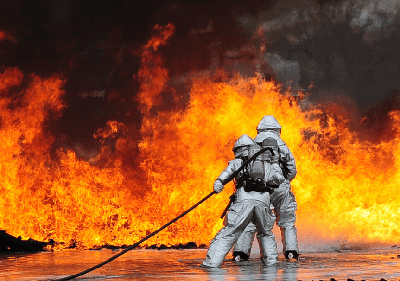

How Dust Explosions Occur

You’re probably familiar with the fire triangle; fuel (in this case dust particles), heat, and  oxygen. When dust particles disperse in sufficient size and concentration, this can cause rapid combustion. If the combustion is confined to a specific area, such as a vessel, room, or building, the increase in pressure can cause an explosion. If the initial explosion dislodges more accumulated dust into the air, and it ignites, this can cause one or more catastrophic secondary explosions. This can result in many deaths as well as the destruction of the associated buildings.

oxygen. When dust particles disperse in sufficient size and concentration, this can cause rapid combustion. If the combustion is confined to a specific area, such as a vessel, room, or building, the increase in pressure can cause an explosion. If the initial explosion dislodges more accumulated dust into the air, and it ignites, this can cause one or more catastrophic secondary explosions. This can result in many deaths as well as the destruction of the associated buildings.

Is Your Industry at Risk for Explosive Dust?

Industries that could expose workers to the dangers of explosive dust include:

- Metalworking

- Agriculture

- Chemical manufacturing

- Pharmaceuticals

- Plastics

- Energy production from fossil fuels

Minimizing Exposure to Explosive Dust

You can minimize and prevent explosive dust hazards in your work environment in the following ways:

- Install dust control filtration: To ensure that your employees are protected from serious injury from combustible dust explosions, the Occupational Safety and Health Administration (OSHA) recommends that you implement dust collection systems. These appliances extract potentially combustible particles from the work environment.

- Minimize the buildup of dust: OSHA also recommends that you prevent dust from accumulation on work area floors and other surfaces, such as shelves and ledges. Taking proactive measures, such as using filtrations systems to reduce dust throughout the work environment will protect your employees from explosion risks. Portable filtration systems are particularly useful as they can be moved to various work areas as needed.

- Employee training: Make sure that your employees are sufficiently trained to know how to utilize dust prevention methods and how to react in case of an emergency involving combustible dust.

How Sledge Tech Can Help You Protect Your Workers

Sledge Tech provides industrial dust collection and filtration solutions for all common industrial applications. You can choose from several options:

- Wet Downdraft Tables: Sledge Tech’s Storm Wet Downdraft Tables use water filtration to extinguish sparks and capture combustible and explosive dust, such as aluminum, magnesium, and titanium. We offer a range of worksurface sizes to suit your needs. All units are self-contained and NFPA-compliant.

- Wet Dust Collectors: Sledge Tech’s Tsunami Wet Dust Collectors are fully NFPA-compliant. They are designed for the safe collection of combustible and explosive dust such as aluminum, magnesium, and titanium. After being drawn through the water filter, contaminants bond with suspended water droplets and are extinguished. They are then drained to the collector for safe removal.

Keeping your employees safe is a top priority. If you would like to find out more about Sledge Tech explosive dust collection solutions or to request a quote, you can reach us at (706) 622-3039.